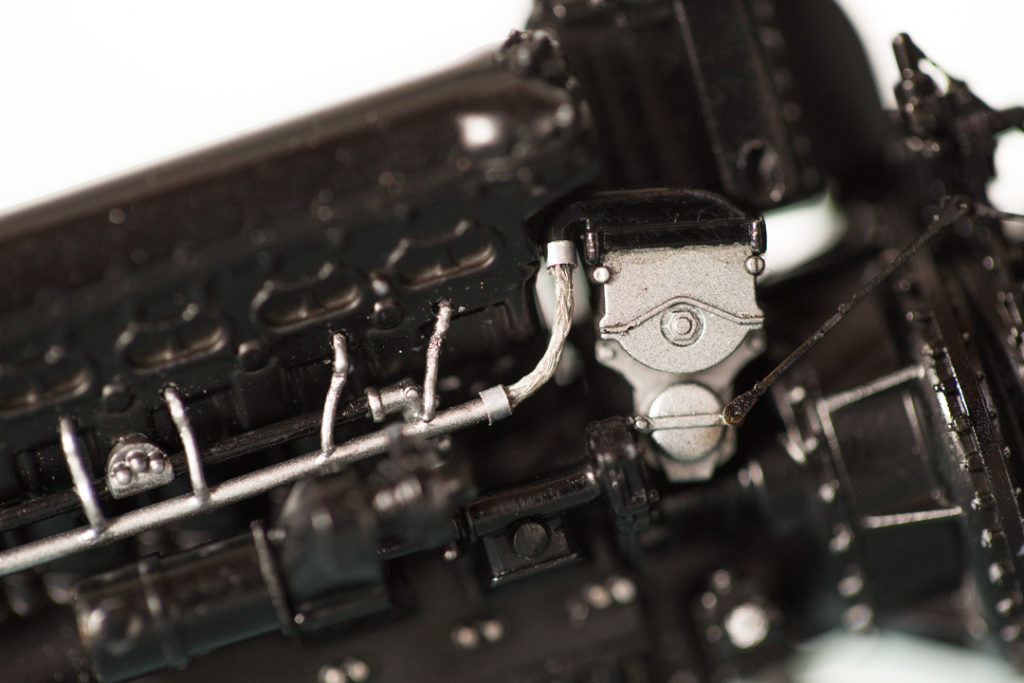

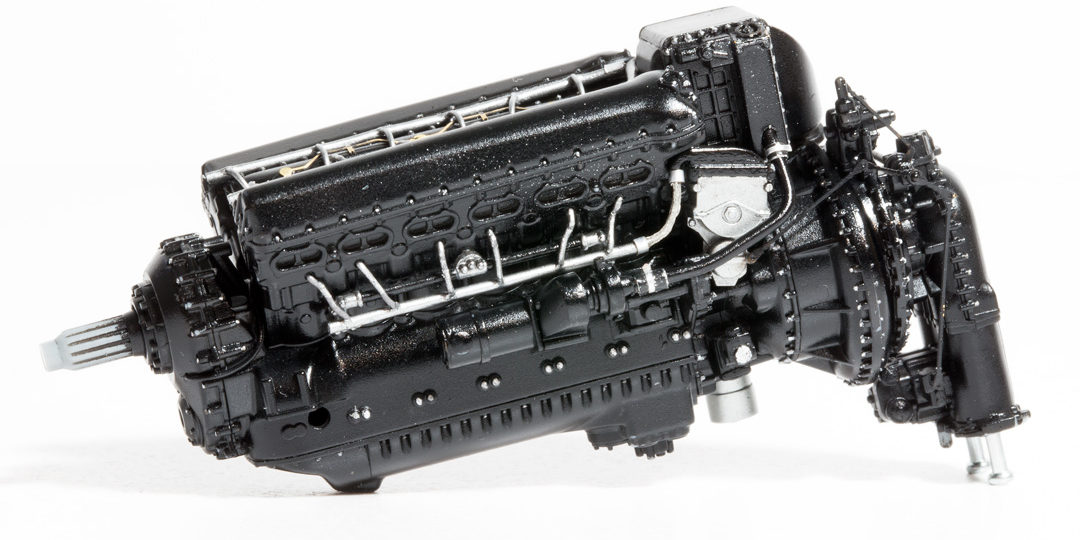

I finally finished up the exhaust ignition harnesses. I had a lot of trouble with these compared to the intake ignition harnesses. With the top harnesses I was able use copper wire and “fudge” the location of where the ignition lines connect to the spark plugs since they are hidden from the intake covers. However, with the exhaust wires I had to insert them in the engine since they are visible. Hats off to Tamiya for molding these holes into the plastic to make for an easy drill out. Instead of copper, I went with lead wire from UMM-USA which is MUCH more flexible than the copper wire. The lead wire made it easier to get those suckers in the spark plug holes. I love the look of those braided lines from Detail Master that attach the ignition harness to the magnetos. Also, I got the Eduard linkages attached to the control shaft at the rear of the motor. Do you ever feel like you could rebuild the real engine after one of your builds?

The lead wire from UMM-USA.

I used a 0.030” styrene rod for the ignition harness and lead wire for the spark plugs wires. I used aluminum from a soda can to create the connectors on the end of the braided line. You can see the Eduard linkage attached to the bottom of the magneto.

I used a 0.030” styrene rod for the ignition harness and lead wire for the spark plugs wires. I used aluminum from a soda can to create the connectors on the end of the braided line. You can see the Eduard linkage attached to the bottom of the magneto.

that is an awesome build what size wire was that? your help would be greatly appreciated

Thanks for the kind words! I couldn’t tell you off the top of my head the wiring size. It was one of the lead wiring offerings from UMM-USA.

I know exactly what you mean. A rebuild would be easy after this! I’m currently detailing a 1/24 Merlin from an old Airfix Hurricane and the amount of research needed is unreal. Oil System, Fuel, Coolant, CSU, Vacuum pump, Compressor… the list is endless (Basically everything Airfix got wrong)

Plenty of material out there along with a little guesswork and I should get there 🙂

Awesome work though, Love the idea of the braiding for the Magnetos