MERLIN MUSTANG: HISTORY OF THE P-51

*I am constantly updating this page so please check back often.

Last Updated: 6/4/2021

Mustang! Is there a name that better embodies the essence of sleekness and power than a wild stallion? The engineers at North American Aviation (NAA) in Inglewood, California must have been thinking the same thing when they developed the iconic design of the P-51 Mustang. The Mustang airframe is an aerodynamic masterpiece. However, with the progression of the air war and the introduction of high altitude bombing campaigns, the Mustang needed an engine boost to keep up. Now, this isn’t a criticism of the 1,120 hp, twelve cylinder, supercharged, Allison V-1710 engine that powered the P-51A and the Royal Air Forces Mustang II version. The Allison-powered Mustang was designed to be a low altitude performer and could reach a max speed of 415 mph at 10,400ft with the single-stage, single-speed supercharger. The downfall of this engine is the drastic decline in performance at higher altitudes and with the bombers flying at 30,000ft the Mustang needed a new power plant. Luckily, across the pond was an engine that would make the P-51 Mustang one of the most famous fighter aircraft of all time. The Rolls-Royce Merlin.

THE MESSENGER

In 1942, Wing Commander Ian Campbell-Orde, commanding officer of the Air Fighting Development Unit (AFDU) at Duxford Aerodrome in England, was staring out his window at a brand new Allison-powered Mustang (AG422). He knew the numbers, he knew the performance, he knew it was the most aerodynamically perfect plane he had. He called up Ronnie Harker, a Rolls-Royce service liaison pilot, to fly the new Mustang. On April 30th, 1942, Harker took to the air and after thirty minutes of flight time he was blown away by what the Mustang could do. What it could do at lower altitudes of course. Once Harker took the Alison upwards thought, he hit the limit of the engine. Luckily, he had the perfect solution with his company’s two stage supercharged Merlin engine. The test was all about the airframe, even with the lower powered Allison, it was still faster than the current Spitfire Mk V already sporting a version of the more powerful Merlin. Harker wrote to Rolls-Royce with persuasive words to get their engine in the Mustang and as a result a legend was born.

This Mustang Mk I AG422 was the aircraft that Ronnie Harker, a Rolls-Royce service liaison pilot, flew on April 30th, 1942. This flight resulted in the testing of the Rolle-Royce Merlin in the Mustang airframe. Months later the most famous fighter of World War II was created. The photograph also shows the early short air scoop for the Allison’s carburetor. This arrangement caused, at different air speeds and angles of attack, a non-uniform flow of air to the engine which resulted in surging. This problem was solved by slightly raising the inlet and extending the lip closer to the propeller. These early Mustangs were camouflaged in Earth and Green upper surfaces and Sky Type S undersides. Upper wing roundels were red and blue while those on the fuselage sides were, from outside in, yellow, blue, white and red. Finally, the underwing roundels were blue, white and red. ©Eric Simms Memorial Collection

MERLIN MAGIC

The Rolls-Royce Merlin is a 12 cylinder liquid-cooled 27-liter (1,649 cu in) supercharged powerhouse. It first ran in 1933, and entered production in 1936, most notably in the Hawker Hurricane and Spitfire. With the air war ramping up in Europe, the British based Rolls-Royce company was in dire need of help producing the Merlin to keep up with demand. In August of 1940, Britain and Rolls-Royce came to the United States looking for a company to produce the engine under license to fulfill the needs of the British Airforce. The Packard Motor Car Company in Detroit, Michigan answered the call and by August, 1941 the first Packard-built Merlin spun a propeller.

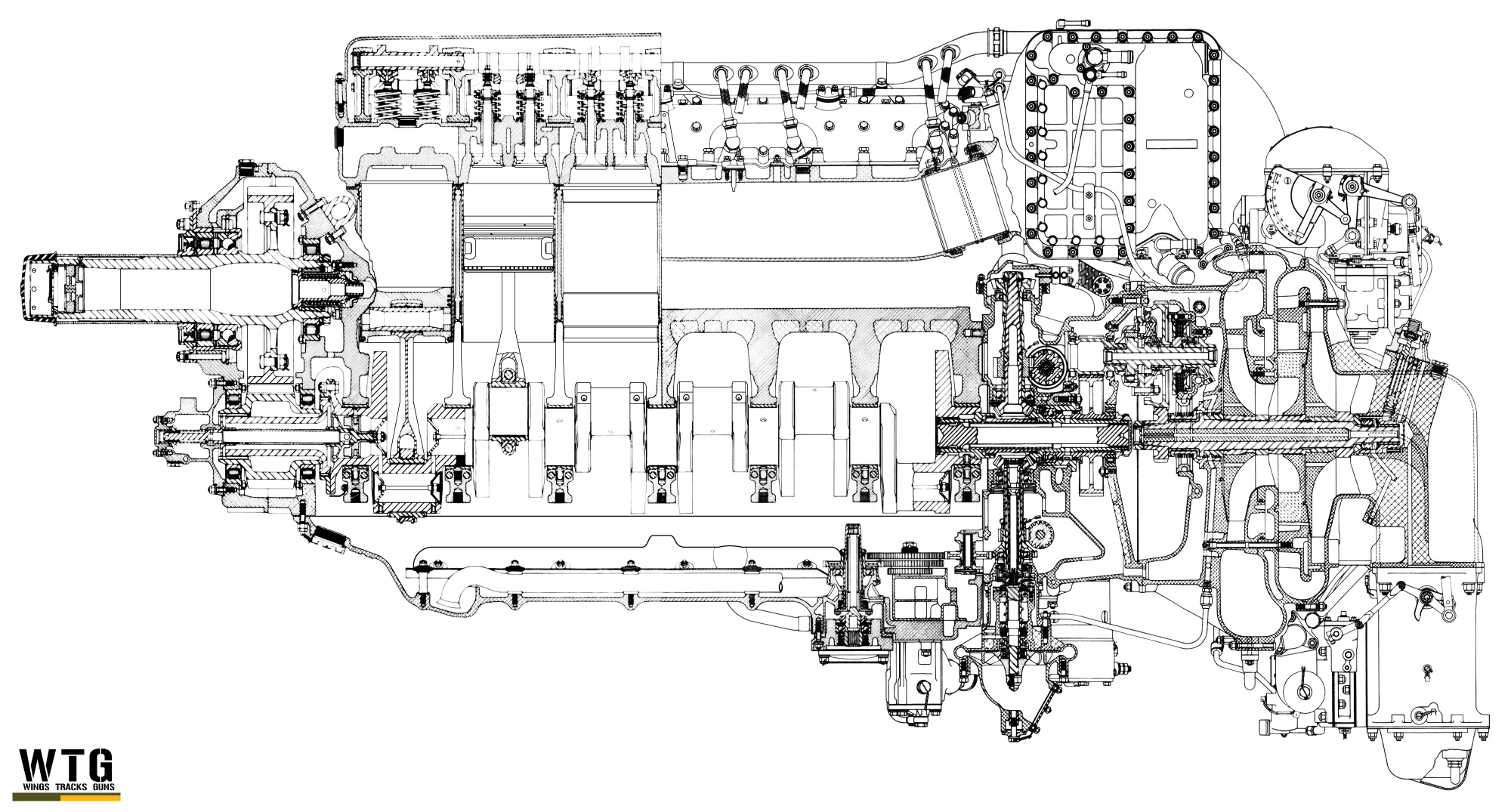

A cross section of a Packard built Rolls-Royce Merlin engine from the V-1650 series.

Early models of the Packard-built Merlin were used mainly for the British Avro Lancaster’s and the American Curtiss P-40Fs. This model was designated as V-1650-1 by the American Military, the V denoting the V-12 configuration and the 1650 signifying the cubic inches (actual cubic inches were 1649 but the figure was rounded up). Like the Allison engine, this model lacked high altitude performance due to the single-stage supercharger. To counter this issue, the Rolls-Royce team developed a two-stage, two speed supercharger attached to the back of the engine and designated it the Merlin 68 in March of 1941. This model was later produced by Packard as the V-1650-3 and became known as the “high altitude” Merlin destined for the P-51.

The “high altitude” Merlin (V-1650-3) attributes it’s characteristics to the design of its two-stage, two speed supercharger design. This supercharger used a Wright designed drive quill that consisted of two impellers on the same shaft. The impellers were controlled by a hydraulic clutch that would select the gear ratio (6.391:1 low ratio and 8.095:1 high ratio) based on altitude. This ratio was automatically controlled (could be changed manually) and usually changed around 20,000ft depending on the amount of ram air. This change in ratio allowed the ram air coming from the under nose intake to have an atmosphere at the cylinders that could produce more horsepower at 24,000ft than the Allison-powered Mustang could at full takeoff power!

A cutout diagram of the Merlin engine two stage supercharger setup. The Merlin aftercooler was incorporated between the second stage compressor and the intake manifold to further reduce the charge temperature to prevent fuel-air charge pre-detonation.

While the Packard Merlin V-1650-3 put the Mustang at the top of the performance charts for US fighters, it still had more to give. As a result of mission reports from air-to-air engagements building up, the upper echelons stepped in and wanted to tweak the power curve to put higher performance between altitudes where most battles occurred. Packard went back to Rolls-Royce for plans for their “low-level” engine named the Merlin 69. This version used different supercharger impeller gear ratios (5.802:1 low ratio and 7.349:1 high ratio) that favored more horsepower at takeoff and through the middle altitudes of 8,500ft through 21,400ft. Which was right in the wheelhouse of altitudes where a majority of air battles occurred during World War II. The impeller controller changed over to the high blower at 14,500ft, compared to 20,000ft for the V-1650-3. However, because of this new supercharger gear ratio, the engine had less horsepower above 21,400ft than the “high altitude” Merlin. This Packard Merlin would be known as the V-1650-7 and would be the go to engine for the Mustang.

A table showing the horsepower ranges for the Packard Merlin V-1650-3 and V-1650-7 at various power settings and altitudes.

STALLION IS BORN

The venture towards the perfect Merlin Mustang was a joint endeavor between the U. S. Army Airforce and the British. While both sides were collaborating throughout the project, NAA came out on top with the streamline airframe of the XP-78 NA-101 (the initial designation of the Merlin Mustang prototype with the ‘X’ standing for experimental and the NA-101 being the factory designation charge number) to house the big engine. This prototype took only six weeks to get in the air! The attempted British designated Mustang X was not the prettiest aircraft with prominent scoops and ducts to cool the Merlin. With the first successful flights of the XP-78, Britain decided to drop the project and wait for the NAA production version.

This Mustang carries the designation of XP-51B with the serial number 41-37352. It is one of three P-51A Mustangs converted to house the Packard built Merlin V-1650-3 engine. Notice the North American Aviation logo on the tail.

The test dummy for the new Merlin was a P-51A Mustang conversion carrying the USAAF serial number of 41-37352. Even though this airframe resembled the lines of its original form as a P-51A, it was vastly different. First, the forward fuselage was redesigned and strengthened with new motor mounts. The original Allison V-1710 engine weighed in at 1335lbs while the Packard Merlin tipped the scales at 1690lbs. Also, the four-bladed, 11’2″ diameter, constant-speed, variable-pitch Hamilton Standard 24D50 propeller brought even more weight to the front of the aircraft compared to the three-bladed Allison propeller. The carburetor air intake was moved from above to below the nose in order to accommodate the Merlin’s updraft induction system. The air scoop under the fuselage was also revamped, which will be discussed later in the article. While the first Merlin P-51A sports four 20mm cannons, NAA planned to move to 50cal Browning machine guns strictly in the wings, removing the nose guns once they nailed down the engine conversion.

On November 30th,1942, test pilot Robert Chilton took off from Mines Field in southern California – the airfield that is now Los Angeles International Airport, in the first Merlin-powered Mustang. Not only was the engine new, NAA dropped the XP-78 designation and renamed the prototype XP-51B (NA-101) 44 days earlier on September 14th. Chilton skipped the usual speed runs and went straight towards the clouds to prove the Merlin had made the ultimate Mustang. At 20,000ft the automatic supercharger gear flipped to high speed and the machine kept climbing, eventually reaching altitudes above 30,000ft. Chilton was blown away by the performance and maneuverability of the high flying Mustang. However, eventually the cooling system had an issue and Chilton brought the prototype down with a white trail of smoke.

A diagram of the P-51 Mustang coolant system for the Packard Merlin. The engine is cooled by liquid in two separate cooling systems. The first system cools the engine, the second (called the after-cooling system) cools the supercharger fuel-air mixture. Each performs a separate function and the systems are not connected in any way. They both pass through a single large radiator, but in different compartments. It also has an oil cooler radiator that sits in front of the main radiator.

The North American Aviation Company went to the Harrison Radiator Division of General Motors to redesign the coolant system and rid the XP-51B of its overheating issues. With a new radiator for the engine and supercharger and a separate oil radiator, the Mustang was tamed. The new system consists of a single air scoop aft of the cockpit under the fuselage. The first system cools the engine, the second (called the after-cooling system) cools the supercharger fuel-air mixture and the third cools the oil. The engine and supercharger radiator was a single unit however, the two coolant systems were completely separate. The two radiators shared the air coming from the under wing intake with the oil radiator mounted in front of the big engine radiator. Each radiator had their own controllable outlet door to keep the temperatures in the green.

A diagram showing the cooling system of Packard Merlin equipped P-51 Mustang. There are two complete and separate cooling systems. One system, the engine cooling system, is used to cool the engine. The other, the aftercooling system, cools the supercharged fuel-air mixture. Coolant from each system passes through the respective portion of the dual radiator, in the aft portion of the air scoop on the underside of the fuselage. The radiator is actually two radiators constructed as a single unit with separate cores. An electrically controlled flap-type door is used to control the airflow through the radiator. In case of actuator failure, an emergency handle opens the coolant flap to lower temperature. The coolant solution consists of water and ethylene glycol in varying percentages, depending on outside operating temperatures.

A detailed schematic of the P-51 Mustang coolant system showing the Harrison radiator, supply/return lines to and from the engine, and the radiator/aftercooler matrix.

With the coolant issue fixed, NAA took two more Allison Mustangs (serial numbers 41-37320 and 41-37469) and converted them to house the Merlin and the new radiators. Chilton was able to put the radiators to work and maintain a speed of 414 mph at 29,800ft, over 100 mph faster than the Allison-powered Mustang at that altitude! Needless to say, the new Merlin had made one of the best fighters of the war, allowing the Allies to compete with the likes of the Bf 109 and Fw 190.

P-51’s on the assembly line at the North American Aviation factory in Inglewood, California. Library of Congress

Before the XP-51B even hit the skies, the USAAF was so confident in the new motor that on August 26th,1942 the Airforce ordered 400 P-51B-1-NA Mustangs. Originally, the plan was to continue producing the Allison-powered P-51A alongside the Merlin-powered P-51B. However, eventually NAA and the US favored the overall performance of the Merlin Mustang and slashed the production of the P-51A. With production in full swing of the 2200 Merlin Mustangs ordered by the USAAF, the factory at Inglewood did some expanding and rearranging to satisfy the need of their new baby. The assembly lines for the B-25 were moved to Kansas City to make room in the stable for the Mustang. The P-51 assembly line was so efficient in its layout and methods that it could pump out 20 Mustangs a day! The need for the Mustang was so great that the USAAF ordered NAA to also expand their Dallas, Texas plant to produce the Mustang. As a result, a new designation schema was created. All Mustangs produced at Inglewood would be known as P-51B’s while the Dallas plant would produce P-51C’s. Both “models” were exactly the same and the only way to differentiate them was by their serial numbers. Similar to NAA, the Packard factory in Detroit also needed help keeping up with production requests of the Merlin from both the US and Britain. To add to Packard’s engine production issues, the USAAF also tasked them with making blocks of spare parts and extra engines for the Packard Merlin 1650-1. This shift in resources delayed NAA from delivering the P-51B order by nearly 60 days. They found relief by partnering with Continental in Muskegon to have their assembly lines filled with Merlin engines. With the Merlin design solid, factories setup, and orders from the US in, the first Merlin P-51B/C was ready to hit the skies.

WARTIME BIRDCAGE

On May 5th, 1943 the first production P-51B-1NA (43-12093) took its maiden flight in California. After the factory finished its expansion in Dallas, the first P-51C-1NT followed four months later on August 5th, 1943. The final production design of the Merlin-powered P-51B/C was as sleek as could be. The perfectly placed air intakes, redesigned front fuselage, and of course the new V-1650-3 engine made a solid, efficient, and deadly weapon for World War II. With four .50cal Browning machine guns in the wings and racks cleared for 500-lbs of bombs, fuel tanks, or rocket tubes the Mustang was ready for war. Inglewood produced 400 P-51B-1-NAs and Dallas produced 250 P-51C-1-NTs.

This P-51B-1-NA, serial number 43-12093, is the first production P-51B off the assembly line at North American Aviation in Inglewood, California on May 5th, 1943.

Ground crew fit a 75 gallon drop tanks to North American P-51B-1-NA Mustang (GQ-I, serial number 43-12451) of the 355th Fighter Squadron, 354th Fighter Group, January 1944. Notice the lack of side air vents in the ram air duct that didn’t come until the P-51B-5-NA. ©Imperial War Museum

Like any aircraft, improvements and enhancements made their way to the production line from the experiences and needs that arose from an aircraft being put through its paces during wartime. The first major upgrade was the addition of rectangular filtered-air side vents to each side of the carburetor ram air duct in the front of the nose. This vent allowed the pilot to close a door in the front of the duct that would prevent ram air from entering through the front of the air intake. This was useful if the duct became obstructed by ice or foreign matter, thus allowing filtered air to enter through the rectangular side vents. Also, to compliment these vents, a new hot air exchange door behind the left rear exhaust stack was added. This door allowed hot air from the exhaust to enter an auxiliary hot air duct connected to the carburetor if engine temperatures needed to be elevated. This auxiliary hot air duct would stay with the Mustang until it switched to the V-1650-7 engine. Another major upgrade that was significant to the airframe was a change to ailerons. The sealed ailerons had an extra hinge added at the wing mounting, bringing the total to three. These changes along with other minor changes were the start of the “block 5” or the P-51B-5-NA at Inglewood and into the P-51C-1-NT line at Dallas. Inglewood produced a total of 800 -5’s.

A crew chief of the 355th Fighter Group working on the engine of a North American P-51B-5-NA Mustang (WR-W, serial number 43-6520) nicknamed “Woody’s Maytag”. This aircraft has the side air vents in the ram air duct along with the auxiliary heat duct behind the exhaust stacks. Also, take note of the white cross under the data block that recognizes this aircraft had the 85 gallon fuselage tank upgrade. This aircraft Failed to Return (FTR) on June 4th, 1944 from an area patrol near St Quentin en Tourmont. Pilot First Officer Henry Davis noted high engine temperatures and turned for home. He eventually lost speed and altitude and ended up flying through 20mm ground fire and lost control and crashed. Henry W Davis was killed in Action (KIA). ©Imperial War Museum

With the addition of the “high altitude” Packard Merlin, the P-51 was ready to get to the height of the bombers. However, there was one issue…fuel. Even having one of the best mile per gallon ratings of any fighter the Allies had, the Mustang still couldn’t make it deep into Germany. Tests have shown that the Merlin Mustang could get around 3.3 miles per gallon as compared to the approximate 1.8 miles per gallon for the P-47 Thunderbolt, the Mustang was a very fuel friendly fighter. Even with the efficiency of the Mustang design, the higher ups of the war departments still required more range due to expanding operations in the European and Pacific theaters.

June 19th, 1943

Major General Barney M. Giles,

This brings to mind very clearly the absolute necessity for building a fighter airplane that can go in and out with the bombers. Moreover, this fighter has to go into Germany. Perhaps we can modify some existing types to do the job. The P-38 has been doing a fine job from North Africa in escorting our B-17s 400 hundred miles or so. Whether this airplane can furnish the same escort against the GAF (German Air Force) on the Western Front is debatable. Our fighter people in the UK claim they can’t stay with the bombers because they are too slow (in cruise mode) and because they (the fighter escort) must have top speed by the time they hit the bombers. The P-38 is not notable for great acceleration, so perhaps it too will not be able to meet the FW’s and 109’s. About six months remain before deep penetrations of Germany begin. Within the next six months, you have got to get a fighter that can protect our bombers. Whether you use an existing type or have to start from scratch is your problem. Get to work on this right away because in January, ’44, I want a fighter escort for our bombers from the UK into Germany.

General Henry H. Arnold

With the demands of General Arnold, NAA started experimenting with adding an additional 85 gallon self-sealing fuel tank mid fuselage behind the cockpit. This would bring the total internal fuel to 269 gallons, and with two 75 gallon two-piece sheet-metal stamped drop tanks the Mustang could carry 419 gallons. This fuel capacity would give the Mustang a combat radius of 705 miles; this included warm-up, takeoff, climb to cruise altitude, loitering/dogfighting time, and the journey home. In mid-March, the USAAF received one time use 110 gallon paper drop tanks. These tanks increased total fuel capacity to 489 gallons along with extending the combat radius even further to around 750 miles.

This chart is from the Flight Manual (NA-5914) of the P-51D Mustang from February 9th, 1945. It shows the varying range distances with the different fuel load out configurations.

To solidify the escort title the Mustang would get additional upgrades to aid in their long missions. There was an outstanding issue of fuel not drawing from the external drop tanks of altitudes above 20,000ft. To combat this loss of fuel pressure NAA pressurized the external tanks to keep fuel flowing to feed the big Merlin. Along with providing enough fuel to the machine, the pilot also needed some attention. The oxygen system was modified and relocated. Higher capacity tanks were installed to provide sufficient oxygen to the pilot on those longer-range operations. The bombers now had the escorts they needed for round trip protection from the Luftwaffe deep into Germany. These upgrades were immediately moved to the production line. On November 29th, 1943, 43-6913 (4th Fighter Group’s future VF-T flown by Captain Don Gentile) emerged from the Buffalo Depot. The Buffalo modification center at the Curtiss Aeroplane and Motor Company was one of a handful of locations where aircraft had post-production changes made before being shipped overseas. It has the Firestone 85 gallon fuselage tank modification, and is also the first P-51B-5-NA with the combat tank pressurization system. It is one of the last 550 B-5-NAs modified after production and is re-identified at Buffalo as a P-51B-7-NA. NAA was also contracted to produce 1600 fuselage kits to retrofit Mustangs already deployed to the European theatre without the new tank. Shipped with these kits, was the 108-page Field Service Bulletin (FSB) 73-95 instructing the install of the tank on all previously produced P-51B-1s, P-51B-5-NAs, P-51C-1s, and the first 50 P-51C-5-NTs. This FSB had comprehensive instructions and diagrams for installing the 85 gallon fuselage tank, the new fuel selector switch with all necessary plumbing and wiring, and everything needed for modifying the oxygen system. Additionally, the battery, radio set and identification friend or foe (IFF) system needed to be relocated to make room for the tank. On December 1st, 1943 the very first complete long-range escort production Mustang (43-7113) took to the sky and the P-51B-10-NA (“block 10”) was born for a total of 398 produced. The Dallas factory continued to roll these changes into their P-51C-1-NT designated Mustangs.

Page 1 and 2 of the of the “NAA Weekly Service News” dated October 30th, 1943 explaining the introduction of the 85-gallon fuselage tanks kits for the P-51B Mustang.

Page four of the NAA Field Service Bulletin’s last update for January 1944 details both the serial number block and the quantity of the aircraft to be modified. Note that provisions to supply complete kits were made for all P-51B-1s, 800 P-51B-5s and the first 400 P-51C-1s. This 108-page document detailed every step required in the modification process for the fitting of the 85-gallon fuselage tank into existing P-51B/Cs in the field.

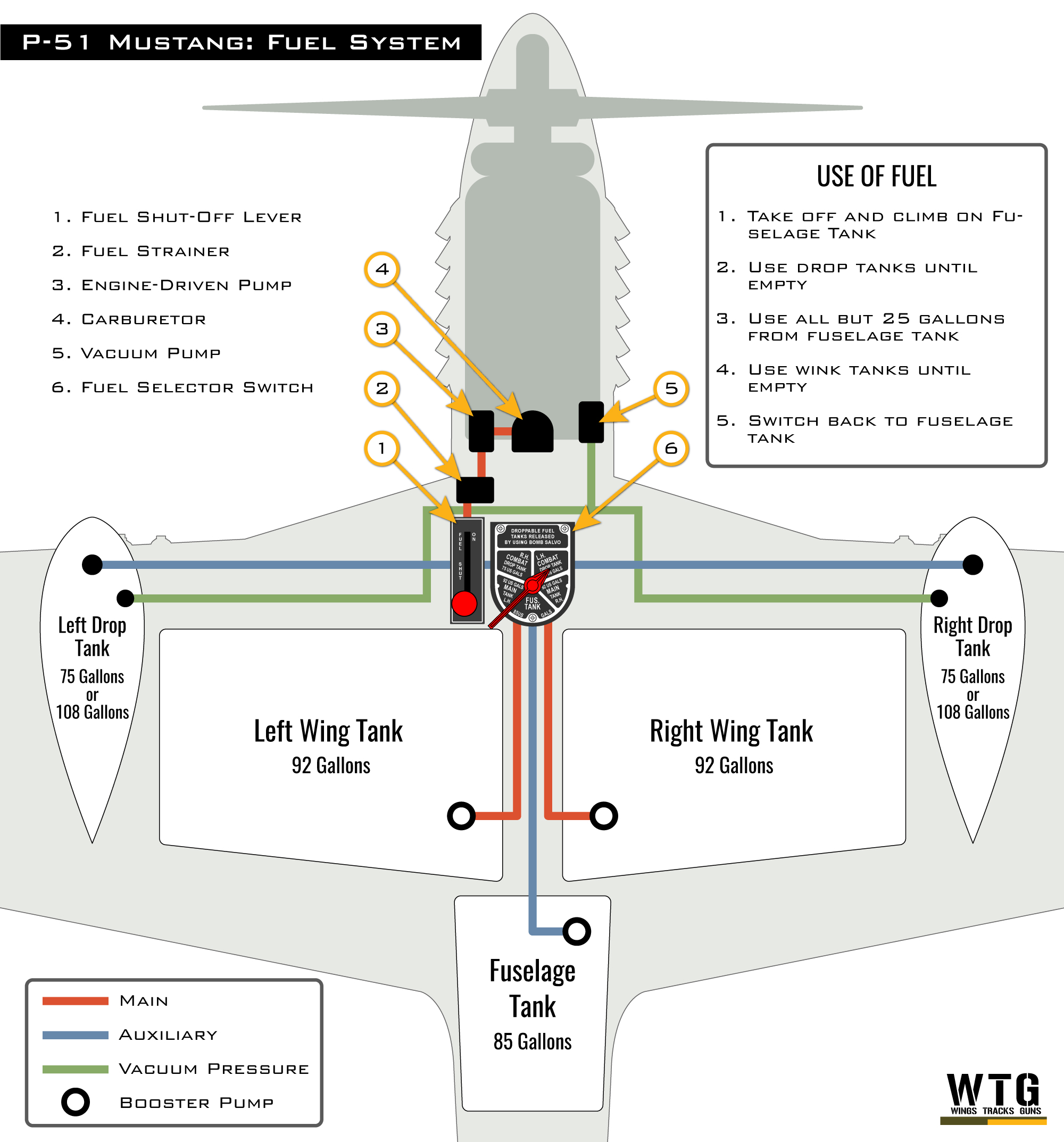

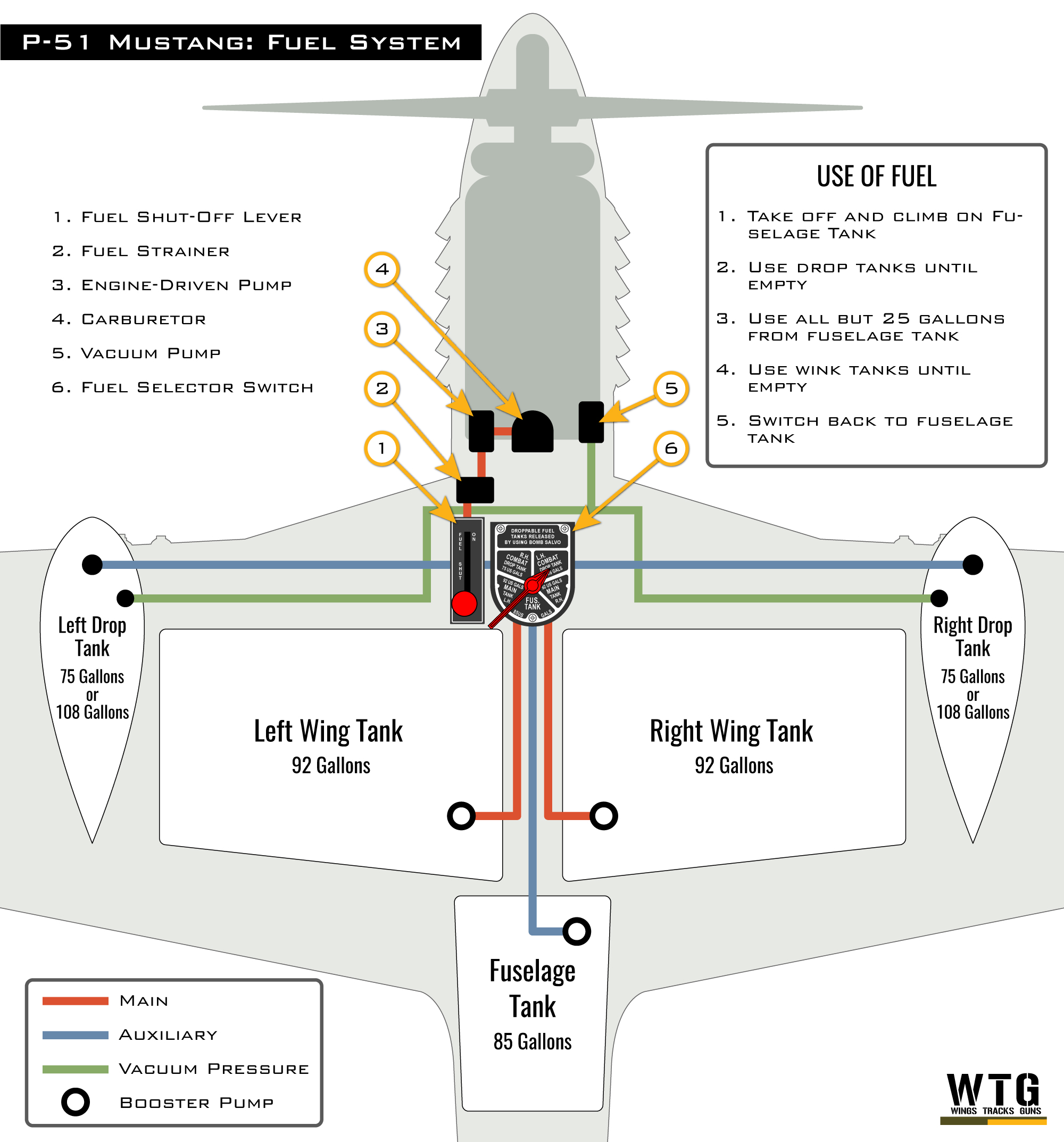

A diagram of the North American P-51 Mustang fuel system. This system has the 85 gallon fuselage tank that was added to the last 550 P-51B-5-NA’s. It came standard from the Inglewood production line starting with the P-51B-10-NA and the Dallas factory continued to roll these changes into their P-51C-1-NT designated Mustangs.

Another significant change that not only affected the olive drab painted Mustang, but every USAAF aircraft, was Technical Order (TO) 07-1-1 issued on December 26th, 1943 by Materiel Command. This order stated that all exterior painting of aircraft be discontinued. A couple days later, NAA released the following guidelines pertaining to the TO in their Weekly Service News Publication Volume 2, Number 20 from January 1st, 1944:

‘Both aircraft and spares to cease application of camouflage paint. Exterior surfaces such as fabric, plywood, magnesium and dural will require protective primers of aluminized coating. Alclad and stainless steel will require no covering. Anti-glare paint will be on top of the fuselage covering forward vision areas to aid the pilot. The wing leading edges will be smoothed as outlined on P-51B/C Series Repair Manual, Report No. NA-5742, with the exception that the camouflage will be deleted and aluminized lacquer applied. The deletion of camouflage will eliminate approximately sixteen pounds of finish from the P-51 Series Airplanes. It is anticipated that the removal of the camouflage will also materially increase speed.’

A cartoon from North American Aviation’s Weekly Service News Publication Volume 2, Number 20 from January 1st, 1944. This cartoon is in reference to the Technical Order 07-1-1 issued on December 26th, 1943 stating that exterior painting of all USAAF aircraft be discontinued.

The goal of going bare to the natural metal finish, besides the man hours, weight, and money savings was not to hide from the enemy but draw them in for a fight. At this point in the war the Allies were gaining complete air dominance and hiding was no longer a necessity however, some pilots disagreed. Once new Mustangs arrived at their theater of war, ground crews and pilots were scrounging up paint and applying their own camouflage schemes.

On September 17th 1943, another big brass demanded change to the Mustang and this time it came from Brigadier General Charles Branshaw. He sent a cable to NAA ordering, “convert Packard Merlin 1650-3 to -7 as soon as possible. Packard to produce supercharger kits as required in the field.” With the introduction of the Packard Merlin V-1650-7 (equivalent to the Rolls-Royce Merlin 65) the performance curve was tweaked to give the Mustang better performance at the altitudes of a majority of the air-to-air engagements during World War II. With an adjustment to the supercharger impeller gear ratios, the Mustang was able to gain more horsepower and speed through the middle altitudes of 8,500ft through 21,400ft. This new engine was installed in P-51B-10-NA 42-106739 and P-51C-1-NT 42-103329 in February 1944. The V-1650-7 addition was the start of the P-51B-15-NA block, the last block change for the P-51B, at Inglewood. With the new engine, Dallas finally got their first block change with the P-51C-5-NT. The California factory produced 390 -15’s and Texas pumped out 450 -5’s

A graph showing the level speed performance of the P-51 Mustang.

VARIANTS

P-51B-1-NA

A profile drawing of a North American P-51B-1-NA Mustang depicting the configuration of “Peg O’ My Heart”, serial number 43-12173 of the 355th Fighter Squadron, 354th Fighter Group. This rendering includes the British Mark II Gunsight with fuselage mounted bead sight, no shrouds around the exhaust, SCR-535 Antenna mast, and bomb racks rated for 500 pounds. The P-51B-1-NA came with the Packard built V-1650-3 Merlin engine.

- Packard Merlin V-1650-3 engine

- 1,490hp at 13,700 ft

- Hamilton Standard 24D50 propeller

- Four-bladed 11’2″ diameter propeller with constant-speed and variable-pitch.

- Laminar flow wings

- Ailerons were sealed with two attachment hinges for connection to the wing.

- Steel diaphragm on the leading edge.

- Three adjustable throw angles of +/-10, 12, and 15 degrees.

- Three “fences” to strengthen the wing skin, two on top and one on the underside.

- Wing hardpoints could support 500 lbs on each wing of bombs or equivalent fuel load.

- A-36 bomb racks adapted for the B/C

- Accepts 75 gallon or 108 gallon drop tanks. One under each wing.

- Four .50 Cal Browning AN/M2 machine guns. Two in each wing.

- 1,260 rounds total

- 350 rounds for each inner gun and 280 rounds for each outer gun

- Under nose air intake for the Merlin updraft supercharger induction system.

- Under fuselage air intake just aft of the cockpit that houses two radiators.

- Engine cooler radiator

- Aftercooler radiator – cools the supercharger fuel-air mixture

- Oil cooler radiator

- Two 92 gallon self sealing fuel tanks, one in each wing.

- Total of 182 gallons internally

- N-3B Gunsight

- SCR-274-A or SCR-522-A Command Radios

- SCR-695, SCR-535, or SCR-695 IFF Radios

P-51B-5-NA

A profile drawing of a North American P-51B-5-NA Mustang depicting the configuration of serial number 43-6437 flown by Lt Col Don Blakeslee. Although a notoriously unreliable aircraft, Blakeslee kept 43-6437 because of its rare Malcolm canopy. On August 7th, 1944, this aircraft was hit by flak strafing a train near Dijon. The pilot at the time was Lt Sidney V Wadsworth who was wounded and became a prisoner of war. This rendering includes the British Mark II Gunsight, shrouds around the exhaust, Malcolm canopy, rectangular filtered-air side vents in the carburetor ram air duct, hot air exchange door behind the left rear exhaust stack, and bomb racks rated for 500 pounds. The P-51B-5-NA came with the Packard built V-1650-3 Merlin engine.

- Addition of carburetor ram air duct side filter vents.

- Addition of hot air exchange door behind the left rear exhaust stack.

- Increased aileron hinge attachments to three at the wing mounts.

- Steel diaphragm on leading edge of left aileron replaced with non-magnetic material of equal weight. Steel diaphragm messed with the magnetic compass.

- Added A-1 head assembly to N-3B Gunsight

P-51B-7-NA

A profile drawing of a North American P-51B-7-NA Mustang depicting the configuration of “Wizard Kite”, serial number 43-6945. This aircraft was shot down by enemy anti-aircraft fire on July 8th, 1944. The pilot James Lowder was killed. This rendering includes the British Mark II Gunsight, rearview mirror, shrouds around the exhaust stacks, SCR-535 Antenna mast, rectangular filtered-air side vents in the carburetor ram air duct, hot air exchange door behind the left rear exhaust stack, bomb racks rated for 500 pounds, and 85 gallon fuselage tank. Notice the 6in. x 6in. cross next to the data block on the left side of the fuselage. The main reason is to identify these Mustang for the pilots, to warn them that they are to be flown with care when fully fueled due to the aft movement of the CG limit from the new 85 gallon fuselage tank. The P-51B-7-NA came with the Packard built V-1650-3 Merlin engine.

The “Block 7” Mustangs were modified P-51B-5-NAs at the Buffalo Depot, not Mustangs directly off the NAA production line.

- 85 gallon fuselage tank

- New fuel selector switch

- Larger oxygen tanks and relocated due to new fuselage tank.

- External fuel tank pressurization system installed.

- Radio equipment relocated due to new fuselage tank.

P-51B-10-NA

A profile drawing of a North American P-51B-10-NA Mustang depicting the configuration of “Shoo Shoo Baby”, serial number 42-106447 of the 364th Fighter Squadron, 357th Fighter Group, 8th Air Force. This aircraft was shot down by enemy anti-aircraft fire on July 8th, 1944. This rendering includes the British Mark II Gunsight, no shrouds around the exhaust stacks, AN-104-A antenna mast, rectangular filtered-air side vents in the carburetor ram air duct, hot air exchange door behind the left rear exhaust stack, bomb racks rated for 500 pounds, combat tank pressurization system, and 85 gallon fuselage tank. The P-51B-10-NA came with the Packard built V-1650-3 Merlin engine.

- 85 gallon fuselage tank

- New fuel selector switch

- Larger oxygen tanks and relocated due to new fuselage tank.

- External fuel tank pressurization system installed.

- Radio equipment relocated due to new fuselage tank.

- AN-104-A Antenna Mast

P-51B-15-NA

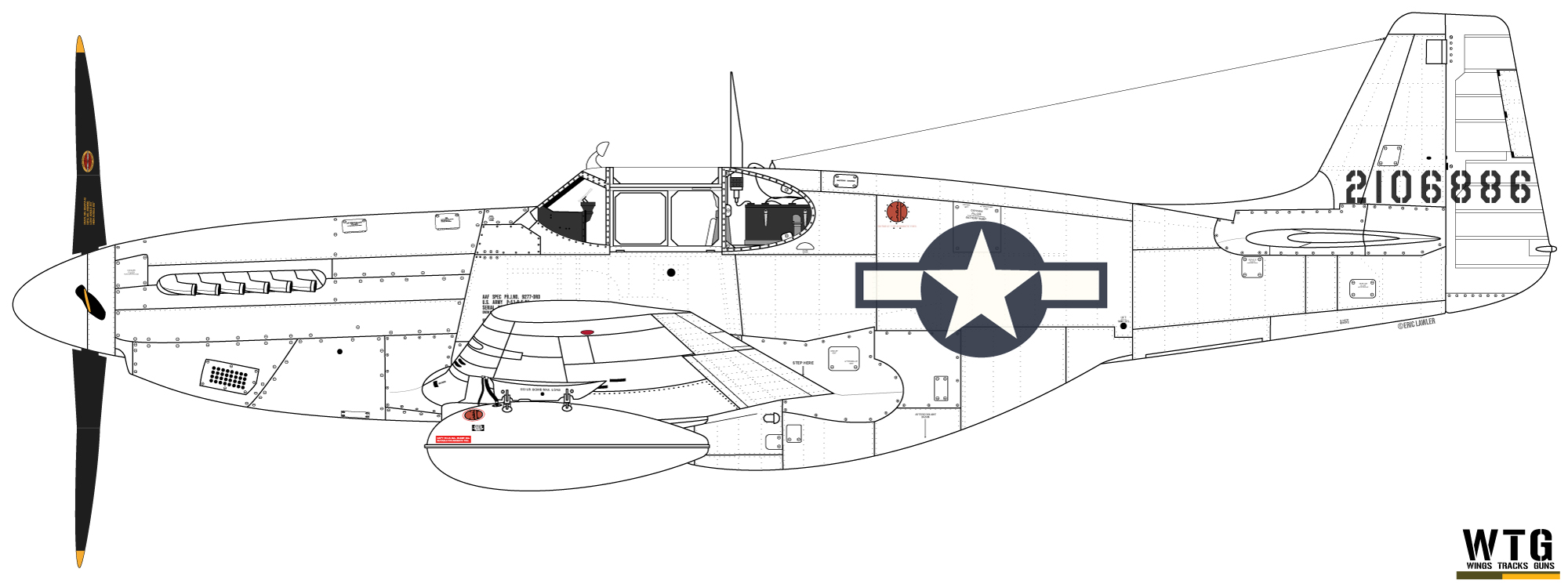

A profile drawing of a North American P-51B-15-NA Mustang depicting the configuration of “Swede”, serial number 42-106886 of the 504th Fighter Squadron, 339th Fighter Group. This rendering includes the British Mark II Gunsight, dorsal fin, no shrouds around the exhaust stacks, AN-104-A antenna mast, rectangular filtered-air side vents in the carburetor ram air duct, bomb racks rated for 500 pounds, combat tank pressurization system, and 85 gallon fuselage tank. This aircraft was had a natural metal finish. The P-51B-15-NA came with the Packard built V-1650-7 Merlin engine.

- Packard Merlin V-1650-7

- 1,590hp at 8,500 ft

MERLIN MUSTANG

Last Updated: 6/4/2021

Mustang! Is there a name that better embodies the essence of sleekness and power than a wild stallion? The engineers at North American Aviation (NAA) in Inglewood, California must have been thinking the same thing when they developed the iconic design of the P-51 Mustang. The Mustang airframe is an aerodynamic masterpiece. However, with the progression of the air war and the introduction of high altitude bombing campaigns, the Mustang needed an engine boost to keep up. Now, this isn’t a criticism of the 1,120 hp, twelve cylinder, supercharged, Allison V-1710 engine that powered the P-51A and the Royal Air Forces Mustang II version. The Allison-powered Mustang was designed to be a low altitude performer and could reach a max speed of 415 mph at 10,400 feet with the single-stage, single-speed supercharger. The downfall of this engine is the drastic decline in performance at higher altitudes and with the bombers flying at 30,000 feet the Mustang needed a new power plant. Luckily, across the pond was an engine that would make the P-51 Mustang one of the most famous fighter aircraft of all time. The Rolls-Royce Merlin.

THE MESSENGER

In 1942, Wing Commander Ian Campbell-Orde, commanding officer of the Air Fighting Development Unit (AFDU) at Duxford Aerodrome in England, was staring out his window at a brand new Allison-powered Mustang (AG422). He knew the numbers, he knew the performance, he knew it was the most aerodynamically perfect plane he had. He called up Ronnie Harker, a Rolls-Royce service liaison pilot, to fly the new Mustang. On April 30th, 1942, Harker took to the air and after thirty minutes of flight time he was blown away by what the Mustang could do. What it could do at lower altitudes of course. Once Harker took the Alison upwards thought, he hit the limit of the engine. Luckily, he had the perfect solution with his company’s two stage supercharged Merlin engine. The test was all about the airframe, even with the lower powered Allison, it was still faster than the current Spitfire Mk V already sporting a version of the more powerful Merlin. Harker wrote to Rolls-Royce with persuasive words to get their engine in the Mustang and as a result a legend was born.

This Mustang Mk I AG422 was the aircraft that Ronnie Harker, a Rolls-Royce service liaison pilot, flew on April 30th, 1942. This flight resulted in the testing of the Rolle-Royce Merlin in the Mustang airframe. Months later the most famous fighter of World War II was created. The photograph also shows the early short air scoop for the Allison’s carburetor. This arrangement caused, at different air speeds and angles of attack, a non-uniform flow of air to the engine which resulted in surging. This problem was solved by slightly raising the inlet and extending the lip closer to the propeller. These early Mustangs were camouflaged in Earth and Green upper surfaces and Sky Type S undersides. Upper wing roundels were red and blue while those on the fuselage sides were, from outside in, yellow, blue, white and red. Finally, the underwing roundels were blue, white and red. ©Eric Simms Memorial Collection

MERLIN MAGIC

The Rolls-Royce Merlin is a 12 cylinder liquid-cooled 27-liter (1,649 cu in) supercharged powerhouse. It first ran in 1933, and entered production in 1936, most notably in the Hawker Hurricane and Spitfire. With the air war ramping up in Europe, the British based Rolls-Royce company was in dire need of help producing the Merlin to keep up with demand. In August of 1940, Britain and Rolls-Royce came to the United States looking for a company to produce the engine under license to fulfill the needs of the British Airforce. The Packard Motor Car Company in Detroit, Michigan answered the call and by August, 1941 the first Packard-built Merlin spun a propeller.

A cross section of a Packard built Rolls-Royce Merlin engine from the V-1650 series.

Early models of the Packard-built Merlin were used mainly for the British Avro Lancaster’s and the American Curtiss P-40Fs. This model was designated as V-1650-1 by the American Military, the V denoting the V-12 configuration and the 1650 signifying the cubic inches (actual cubic inches were 1649 but the figure was rounded up). Like the Allison engine, this model lacked high altitude performance due to the single-stage supercharger. To counter this issue, the Rolls-Royce team developed a two-stage, two speed supercharger attached to the back of the engine and designated it the Merlin 68 in March of 1941. This model was later produced by Packard as the V-1650-3 and became known as the “high altitude” Merlin destined for the P-51.

The “high altitude” Merlin (V-1650-3) attributes it’s characteristics to the design of its two-stage, two speed supercharger design. This supercharger used a Wright designed drive quill that consisted of two impellers on the same shaft. The impellers were controlled by a hydraulic clutch that would select the gear ratio (6.391:1 low ratio and 8.095:1 high ratio) based on altitude. This ratio was automatically controlled (could be changed manually) and usually changed around 20,000ft depending on the amount of ram air. This change in ratio allowed the ram air coming from the under nose intake to have an atmosphere at the cylinders that could produce more horsepower at 24,000ft than the Allison-powered Mustang could at full takeoff power!

A cutout diagram of the Merlin engine two stage supercharger setup. The Merlin aftercooler was incorporated between the second stage compressor and the intake manifold to further reduce the charge temperature to prevent fuel-air charge pre-detonation.

While the Packard Merlin V-1650-3 put the Mustang at the top of the performance charts for US fighters, it still had more to give. As a result of mission reports from air-to-air engagements building up, the upper echelons stepped in and wanted to tweak the power curve to put higher performance between altitudes where most battles occurred. Packard went back to Rolls-Royce for plans for their “low-level” engine named the Merlin 69. This version used different supercharger impeller gear ratios (5.802:1 low ratio and 7.349:1 high ratio) that favored more horsepower at takeoff and through the middle altitudes of 8,500ft through 21,400ft. Which was right in the wheelhouse of altitudes where a majority of air battles occurred during World War II. The impeller controller changed over to the high blower at 14,500ft, compared to 20,000ft for the V-1650-3. However, because of this new supercharger gear ratio, the engine had less horsepower above 21,400ft than the “high altitude” Merlin. This Packard Merlin would be known as the V-1650-7 and would be the go to engine for the Mustang.

A table showing the horsepower ranges for the Packard Merlin V-1650-3 and V-1650-7 at various power settings and altitudes.

STALLION IS BORN

The venture towards the perfect Merlin Mustang was a joint endeavor between the U. S. Army Airforce and the British. While both sides were collaborating throughout the project, NAA came out on top with the streamline airframe of the XP-78 NA-101 (the initial designation of the Merlin Mustang prototype with the ‘X’ standing for experimental and the NA-101 being the factory designation charge number) to house the big engine. This prototype took only six weeks to get in the air! The attempted British designated Mustang X was not the prettiest aircraft with prominent scoops and ducts to cool the Merlin. With the first successful flights of the XP-78, Britain decided to drop the project and wait for the NAA production version.

This Mustang carries the designation of XP-51B with the serial number 41-37352. It is one of three P-51A Mustangs converted to house the Packard built Merlin V-1650-3 engine. Notice the North American Aviation logo on the tail.

The test dummy for the new Merlin was a P-51A Mustang conversion carrying the USAAF serial number of 41-37352. Even though this airframe resembled the lines of its original form as a P-51A, it was vastly different. First, the forward fuselage was redesigned and strengthened with new motor mounts. The original Allison V-1710 engine weighed in at 1335lbs while the Packard Merlin tipped the scales at 1690lbs. Also, the four-bladed, 11’2″ diameter, constant-speed, variable-pitch Hamilton Standard 24D50 propeller brought even more weight to the front of the aircraft compared to the three-bladed Allison propeller. The carburetor air intake was moved from above to below the nose in order to accommodate the Merlin’s updraft induction system. The air scoop under the fuselage was also revamped, which will be discussed later in the article. While the first Merlin P-51A sports four 20mm cannons, NAA planned to move to 50cal Browning machine guns strictly in the wings, removing the nose guns once they nailed down the engine conversion.

On November 30th,1942, test pilot Robert Chilton took off from Mines Field in southern California – the airfield that is now Los Angeles International Airport, in the first Merlin-powered Mustang. Not only was the engine new, NAA dropped the XP-78 designation and renamed the prototype XP-51B (NA-101) 44 days earlier on September 14th. Chilton skipped the usual speed runs and went straight towards the clouds to prove the Merlin had made the ultimate Mustang. At 20,000ft the automatic supercharger gear flipped to high speed and the machine kept climbing, eventually reaching altitudes above 30,000ft. Chilton was blown away by the performance and maneuverability of the high flying Mustang. However, eventually the cooling system had an issue and Chilton brought the prototype down with a white trail of smoke.

A diagram of the P-51 Mustang coolant system for the Packard Merlin. The engine is cooled by liquid in two separate cooling systems. The first system cools the engine, the second (called the after-cooling system) cools the supercharger fuel-air mixture. Each performs a separate function and the systems are not connected in any way. They both pass through a single large radiator, but in different compartments. It also has an oil cooler radiator that sits in front of the main radiator.

The North American Aviation Company went to the Harrison Radiator Division of General Motors to redesign the coolant system and rid the XP-51B of its overheating issues. With a new radiator for the engine and supercharger and a separate oil radiator, the Mustang was tamed. The new system consists of a single air scoop aft of the cockpit under the fuselage. The first system cools the engine, the second (called the after-cooling system) cools the supercharger fuel-air mixture and the third cools the oil. The engine and supercharger radiator was a single unit however, the two coolant systems were completely separate. The two radiators shared the air coming from the under wing intake with the oil radiator mounted in front of the big engine radiator. Each radiator had their own controllable outlet door to keep the temperatures in the green.

A diagram showing the cooling system of Packard Merlin equipped P-51 Mustang. There are two complete and separate cooling systems. One system, the engine cooling system, is used to cool the engine. The other, the aftercooling system, cools the supercharged fuel-air mixture. Coolant from each system passes through the respective portion of the dual radiator, in the aft portion of the air scoop on the underside of the fuselage. The radiator is actually two radiators constructed as a single unit with separate cores. An electrically controlled flap-type door is used to control the airflow through the radiator. In case of actuator failure, an emergency handle opens the coolant flap to lower temperature. The coolant solution consists of water and ethylene glycol in varying percentages, depending on outside operating temperatures.

A detailed schematic of the P-51 Mustang coolant system showing the Harrison radiator, supply/return lines to and from the engine, and the radiator/aftercooler matrix.

With the coolant issue fixed, NAA took two more Allison Mustangs (serial numbers 41-37320 and 41-37469) and converted them to house the Merlin and the new radiators. Chilton was able to put the radiators to work and maintain a speed of 414 mph at 29,800ft, over 100 mph faster than the Allison-powered Mustang at that altitude! Needless to say, the new Merlin had made one of the best fighters of the war, allowing the Allies to compete with the likes of the Bf 109 and Fw 190.

P-51’s on the assembly line at the North American Aviation factory in Inglewood, California.

Before the XP-51B even hit the skies, the USAAF was so confident in the new motor that on August 26th,1942 the Airforce ordered 400 P-51B-1-NA Mustangs. Originally, the plan was to continue producing the Allison-powered P-51A alongside the Merlin-powered P-51B. However, eventually NAA and the US favored the overall performance of the Merlin Mustang and slashed the production of the P-51A. With production in full swing of the 2200 Merlin Mustangs ordered by the USAAF, the factory at Inglewood did some expanding and rearranging to satisfy the need of their new baby. The assembly lines for the B-25 were moved to Kansas City to make room in the stable for the Mustang. The P-51 assembly line was so efficient in its layout and methods that it could pump out 20 Mustangs a day! The need for the Mustang was so great that the USAAF ordered NAA to also expand their Dallas, Texas plant to produce the Mustang. As a result, a new designation schema was created. All Mustangs produced at Inglewood would be known as P-51B’s while the Dallas plant would produce P-51C’s. Both “models” were exactly the same and the only way to differentiate them was by their serial numbers. Similar to NAA, the Packard factory in Detroit also needed help keeping up with production requests of the Merlin from both the US and Britain. To add to Packard’s engine production issues, the USAAF also tasked them with making blocks of spare parts and extra engines for the Packard Merlin 1650-1. This shift in resources delayed NAA from delivering the P-51B order by nearly 60 days. They found relief by partnering with Continental in Muskegon to have their assembly lines filled with Merlin engines. With the Merlin design solid, factories setup, and orders from the US in, the first Merlin P-51B/C was ready to hit the skies.

WARTIME BIRDCAGE

On May 5th, 1943 the first production P-51B-1NA (43-12093) took its maiden flight in California. After the factory finished its expansion in Dallas, the first P-51C-1NT followed four months later on August 5th, 1943. The final production design of the Merlin-powered P-51B/C was as sleek as could be. The perfectly placed air intakes, redesigned front fuselage, and of course the new V-1650-3 engine made a solid, efficient, and deadly weapon for World War II. With four .50cal Browning machine guns in the wings and racks cleared for 500-lbs of bombs, fuel tanks, or rocket tubes the Mustang was ready for war. Inglewood produced 400 P-51B-1-NAs and Dallas produced 250 P-51C-1-NTs.

This P-51B-1-NA, serial number 43-12093, is the first production P-51B off the assembly line at North American Aviation in Inglewood, California on May 5th, 1943.

Ground crew fit a 75 gallon drop tanks to North American P-51B-1-NA Mustang (GQ-I, serial number 43-12451) of the 355th Fighter Squadron, 354th Fighter Group, January 1944. Notice the lack of side air vents in the ram air duct that didn’t come until the P-51B-5-NA. ©IWM

Like any aircraft, improvements and enhancements made their way to the production line from the experiences and needs that arose from an aircraft being put through its paces during wartime. The first major upgrade was the addition of rectangular filtered-air side vents to each side of the carburetor ram air duct in the front of the nose. This vent allowed the pilot to close a door in the front of the duct that would prevent ram air from entering through the front of the air intake. This was useful if the duct became obstructed by ice or foreign matter, thus allowing filtered air to enter through the rectangular side vents. Also, to compliment these vents, a new hot air exchange door behind the left rear exhaust stack was added. This door allowed hot air from the exhaust to enter an auxiliary hot air duct connected to the carburetor if engine temperatures needed to be elevated. This auxiliary hot air duct would stay with the Mustang until it switched to the V-1650-7 engine. Another major upgrade that was significant to the airframe was a change to ailerons. The sealed ailerons had an extra hinge added at the wing mounting, bringing the total to three. These changes along with other minor changes were the start of the “block 5” or the P-51B-5-NA at Inglewood and into the P-51C-1-NT line at Dallas. Inglewood produced a total of 800 -5’s.

A crew chief of the 355th Fighter Group working on the engine of a North American P-51B-5-NA Mustang (WR-W, serial number 43-6520) nicknamed “Woody’s Maytag”. This aircraft has the side air vents in the ram air duct along with the auxiliary heat duct behind the exhaust stacks. Also, take note of the white cross under the data block that recognizes this aircraft had the 85 gallon fuselage tank upgrade. This aircraft Failed to Return (FTR) on June 4th, 1944 from an area patrol near St Quentin en Tourmont. Pilot First Officer Henry Davis noted high engine temperatures and turned for home. He eventually lost speed and altitude and ended up flying through 20mm ground fire and lost control and crashed. Henry W Davis was killed in Action (KIA). ©IWM

With the addition of the “high altitude” Packard Merlin, the P-51 was ready to get to the height of the bombers. However, there was one issue…fuel. Even having one of the best mile per gallon ratings of any fighter the Allies had, the Mustang still couldn’t make it deep into Germany. Tests have shown that the Merlin Mustang could get around 3.3 miles per gallon as compared to the approximate 1.8 miles per gallon for the P-47 Thunderbolt, the Mustang was a very fuel friendly fighter. Even with the efficiency of the Mustang design, the higher ups of the war departments still required more range due to expanding operations in the European and Pacific theaters.

June 19th, 1943

Maj. Gen. Giles,

This brings to mind very clearly the absolute necessity for building a fighter airplane that can go in and out with the bombers. Moreover, this fighter has to go into Germany. Perhaps we can modify some existing types to do the job. The P-38 has been doing a fine job from North Africa in escorting our B-17s 400 hundred miles or so. Whether this airplane can furnish the same escort against the GAF (German Air Force) on the Western Front is debatable. Our fighter people in the UK claim they can’t stay with the bombers because they are too slow (in cruise mode) and because they (the fighter escort) must have top speed by the time they hit the bombers. The P-38 is not notable for great acceleration, so perhaps it too will not be able to meet the FW’s and 109’s. About six months remain before deep penetrations of Germany begin. Within the next six months, you have got to get a fighter that can protect our bombers. Whether you use an existing type or have to start from scratch is your problem. Get to work on this right away because in January, ’44, I want a fighter escort for our bombers from the UK into Germany.

Gen. Arnold

With the demands of General Arnold, NAA started experimenting with adding an additional 85 gallon self-sealing fuel tank mid fuselage behind the cockpit. This would bring the total internal fuel to 269 gallons, and with two 75 gallon two-piece sheet-metal stamped drop tanks the Mustang could carry 419 gallons. This fuel capacity would give the Mustang a combat radius of 705 miles; this included warm-up, takeoff, climb to cruise altitude, loitering/dogfighting time, and the journey home. In mid-March, the USAAF received one time use 110 gallon paper drop tanks. These tanks increased total fuel capacity to 489 gallons along with extending the combat radius even further to around 750 miles.

This chart is from the Flight Manual (NA-5914) of the P-51D Mustang from February 9th, 1945. It shows the varying range distances with the different fuel load out configurations.

To solidify the escort title the Mustang would get additional upgrades to aid in their long missions. There was an outstanding issue of fuel not drawing from the external drop tanks of altitudes above 20,000ft. To combat this loss of fuel pressure NAA pressurized the external tanks to keep fuel flowing to feed the big Merlin. Along with providing enough fuel to the machine, the pilot also needed some attention. The oxygen system was modified and relocated. Higher capacity tanks were installed to provide sufficient oxygen to the pilot on those longer-range operations. The bombers now had the escorts they needed for round trip protection from the Luftwaffe deep into Germany. These upgrades were immediately moved to the production line. On November 29th, 1943, 43-6913 (4th Fighter Group’s future VF-T flown by Captain Don Gentile) emerged from the Buffalo Depot. The Buffalo modification center at the Curtiss Aeroplane and Motor Company was one of a handful of locations where aircraft had post-production changes made before being shipped overseas. It has the Firestone 85 gallon fuselage tank modification, and is also the first P-51B-5-NA with the combat tank pressurization system. It is one of the last 550 B-5-NAs modified after production and is re-identified at Buffalo as a P-51B-7-NA. NAA was also contracted to produce 1600 fuselage kits to retrofit Mustangs already deployed to the European theatre without the new tank. Shipped with these kits, was the 108-page Field Service Bulletin (FSB) 73-95 instructing the install of the tank on all previously produced P-51B-1s, P-51B-5-NAs, P-51C-1s, and the first 50 P-51C-5-NTs. This FSB had comprehensive instructions and diagrams for installing the 85 gallon fuselage tank, the new fuel selector switch with all necessary plumbing and wiring, and everything needed for modifying the oxygen system. Additionally, the battery, radio set and identification friend or foe (IFF) system needed to be relocated to make room for the tank. On December 1st, 1943 the very first complete long-range escort production Mustang (43-7113) took to the sky and the P-51B-10-NA (“block 10”) was born for a total of 398 produced. The Dallas factory continued to roll these changes into their P-51C-1-NT designated Mustangs.

Page 1 and 2 of the of the “NAA Weekly Service News” dated October 30th, 1943 explaining the introduction of the 85-gallon fuselage tanks kits for the P-51B Mustang.

Page four of the NAA Field Service Bulletin’s last update for January 1944 details both the serial number block and the quantity of the aircraft to be modified. Note that provisions to supply complete kits were made for all P-51B-1s, 800 P-51B-5s and the first 400 P-51C-1s. This 108-page document detailed every step required in the modification process for the fitting of the 85-gallon fuselage tank into existing P-51B/Cs in the field.

A diagram of the North American P-51 Mustang fuel system. This system has the 85 gallon fuselage tank that was added to the last 550 P-51B-5-NA’s. It came standard from the Inglewood production line starting with the P-51B-10-NA and the Dallas factory continued to roll these changes into their P-51C-1-NT designated Mustangs.

Another significant change that not only affected the olive drab painted Mustang, but every USAAF aircraft, was Technical Order (TO) 07-1-1 issued on December 26th, 1943 by Materiel Command. This order stated that all exterior painting of aircraft be discontinued. A couple days later, NAA released the following guidelines pertaining to the TO in their Weekly Service News Publication Volume 2, Number 20 from January 1st, 1944:

‘Both aircraft and spares to cease application of camouflage paint. Exterior surfaces such as fabric, plywood, magnesium and dural will require protective primers of aluminized coating. Alclad and stainless steel will require no covering. Anti-glare paint will be on top of the fuselage covering forward vision areas to aid the pilot. The wing leading edges will be smoothed as outlined on P-51B/C Series Repair Manual, Report No. NA-5742, with the exception that the camouflage will be deleted and aluminized lacquer applied. The deletion of camouflage will eliminate approximately sixteen pounds of finish from the P-51 Series Airplanes. It is anticipated that the removal of the camouflage will also materially increase speed.’

A cartoon from North American Aviation’s Weekly Service News Publication Volume 2, Number 20 from January 1st, 1944. This cartoon is in reference to the Technical Order 07-1-1 issued on December 26th, 1943 stating that exterior painting of all USAAF aircraft be discontinued.

The goal of going bare to the natural metal finish, besides the man hours, weight, and money savings was not to hide from the enemy but draw them in for a fight. At this point in the war the Allies were gaining complete air dominance and hiding was no longer a necessity however, some pilots disagreed. Once new Mustangs arrived at their theater of war, ground crews and pilots were scrounging up paint and applying their own camouflage schemes.

On September 17th 1943, another big brass demanded change to the Mustang and this time it came from Brigadier General Charles Branshaw. He sent a cable to NAA ordering, “convert Packard Merlin 1650-3 to -7 as soon as possible. Packard to produce supercharger kits as required in the field.” With the introduction of the Packard Merlin V-1650-7 (equivalent to the Rolls-Royce Merlin 65) the performance curve was tweaked to give the Mustang better performance at the altitudes of a majority of the air-to-air engagements during World War II. With an adjustment to the supercharger impeller gear ratios, the Mustang was able to gain more horsepower and speed through the middle altitudes of 8,500ft through 21,400ft. This new engine was installed in P-51B-10-NA 42-106739 and P-51C-1-NT 42-103329 in February 1944. The V-1650-7 addition was the start of the P-51B-15-NA block, the last block change for the P-51B, at Inglewood. With the new engine, Dallas finally got their first block change with the P-51C-5-NT. The California factory produced 390 -15’s and Texas pumped out 450 -5’s.

A graph showing the level speed performance of the P-51 Mustang.

VARIANTS

P-51B-1-NA

A profile drawing of a North American P-51B-1-NA Mustang depicting the configuration of “Peg O’ My Heart”, serial number 43-12173 of the 355th Fighter Squadron, 354th Fighter Group. This rendering includes the British Mark II Gunsight with fuselage mounted bead sight, no shrouds around the exhaust, SCR-535 Antenna mast, and bomb racks rated for 500 pounds. The P-51B-1-NA came with the Packard built V-1650-3 Merlin engine.

- Packard Merlin V-1650-3 engine

- 1,490hp at 13,700 ft

- Hamilton Standard 24D50 propeller

- Four-bladed 11’2″ diameter propeller with constant-speed and variable-pitch.

- Laminar flow wings

- Ailerons were sealed with two attachment hinges for connection to the wing.

- Steel diaphragm on the leading edge.

- Three adjustable throw angles of +/-10, 12, and 15 degrees.

- Three “fences” to strengthen the wing skin, two on top and one on the underside.

- Wing hardpoints could support 500 lbs on each wing of bombs or equivalent fuel load.

- A-36 bomb racks adapted for the B/C

- Accepts 75 gallon or 108 gallon drop tanks. One under each wing.

- Four .50 Cal Browning AN/M2 machine guns. Two in each wing.

- 1,260 rounds total

- 350 rounds for each inner gun and 280 rounds for each outer gun

- Under nose air intake for the Merlin updraft supercharger induction system.

- Under fuselage air intake just aft of the cockpit that houses two radiators.

- Engine cooler radiator

- Aftercooler radiator – cools the supercharger fuel-air mixture

- Oil cooler radiator

- Two 92 gallon self sealing fuel tanks, one in each wing.

- Total of 182 gallons internally

- N-3B Gunsight

- SCR-274-A or SCR-522-A Command Radios

- SCR-695, SCR-535, or SCR-695 IFF Radios

P-51B-5-NA

A profile drawing of a North American P-51B-5-NA Mustang depicting the configuration of serial number 43-6437 flown by Lt Col Don Blakeslee. Although a notoriously unreliable aircraft, Blakeslee kept 43-6437 because of its rare Malcolm canopy. On August 7th, 1944, this aircraft was hit by flak strafing a train near Dijon. The pilot at the time was Lt Sidney V Wadsworth who was wounded and became a prisoner of war. This rendering includes the British Mark II Gunsight, shrouds around the exhaust, Malcolm canopy, rectangular filtered-air side vents in the carburetor ram air duct, hot air exchange door behind the left rear exhaust stack, and bomb racks rated for 500 pounds. The P-51B-5-NA came with the Packard built V-1650-3 Merlin engine.

- Addition of carburetor ram air duct side filter vents.

- Addition of hot air exchange door behind the left rear exhaust stack.

- Increased aileron hinge attachments to three at the wing mounts.

- Steel diaphragm on leading edge of left aileron replaced with non-magnetic material of equal weight. Steel diaphragm messed with the magnetic compass.

- Added A-1 head assembly to N-3B Gunsight

P-51B-7-NA

A profile drawing of a North American P-51B-7-NA Mustang depicting the configuration of “Wizard Kite”, serial number 43-6945. This aircraft was shot down by enemy anti-aircraft fire on July 8th, 1944. The pilot James Lowder was killed. This rendering includes the British Mark II Gunsight, rearview mirror, shrouds around the exhaust stacks, SCR-535 Antenna mast, rectangular filtered-air side vents in the carburetor ram air duct, hot air exchange door behind the left rear exhaust stack, bomb racks rated for 500 pounds, and 85 gallon fuselage tank. Notice the 6in. x 6in. cross next to the data block on the left side of the fuselage. The main reason is to identify these Mustang for the pilots, to warn them that they are to be flown with care when fully fueled due to the aft movement of the CG limit from the new 85 gallon fuselage tank. The P-51B-7-NA came with the Packard built V-1650-3 Merlin engine.

The “Block 7” Mustangs were modified P-51B-5-NAs at the Buffalo Depot, not Mustangs directly off the NAA production line.

- 85 gallon fuselage tank

- New fuel selector switch

- Larger oxygen tanks and relocated due to new fuselage tank.

- External fuel tank pressurization system installed.

- Radio equipment relocated due to new fuselage tank.

P-51B-10-NA

A profile drawing of a North American P-51B-10-NA Mustang depicting the configuration of “Shoo Shoo Baby”, serial number 42-106447 of the 364th Fighter Squadron, 357th Fighter Group, 8th Air Force. This aircraft was shot down by enemy anti-aircraft fire on July 8th, 1944. This rendering includes the British Mark II Gunsight, no shrouds around the exhaust stacks, AN-104-A antenna mast, rectangular filtered-air side vents in the carburetor ram air duct, hot air exchange door behind the left rear exhaust stack, bomb racks rated for 500 pounds, combat tank pressurization system, and 85 gallon fuselage tank. The P-51B-10-NA came with the Packard built V-1650-3 Merlin engine.

- 85 gallon fuselage tank

- New fuel selector switch

- Larger oxygen tanks and relocated due to new fuselage tank.

- External fuel tank pressurization system installed.

- Radio equipment relocated due to new fuselage tank.

- AN-104-A Antenna Mast

P-51B-15-NA

A profile drawing of a North American P-51B-15-NA Mustang depicting the configuration of “Swede”, serial number 42-106886 of the 504th Fighter Squadron, 339th Fighter Group. This rendering includes the British Mark II Gunsight, dorsal fin, no shrouds around the exhaust stacks, AN-104-A antenna mast, rectangular filtered-air side vents in the carburetor ram air duct, bomb racks rated for 500 pounds, combat tank pressurization system, and 85 gallon fuselage tank. This aircraft was had a natural metal finish. The P-51B-15-NA came with the Packard built V-1650-7 Merlin engine.

- Packard Merlin V-1650-7

- 1,590hp at 8,500 ft

The drawing of P-51B SN 42-106686 is so very correct except for one thing:

There’s apparently no way to attach a file to this Reply to show you the drawing, but when P-51Bs and Cs had Dorsal Fins, they were a little over 10 inches longer than those of the P-51D/Ks. As drawn, the Dorsal Fin extends to Fuselage Station 248, and in reality, it extended forward to Fuselage Station 237¾. I’ve used the “paintbrush” option in my paintshop pro program to draw the approximate length of the Dorsal Fin.

Thank you.

I understood the P-51 had limited range and could not accompany the bombers as they flew over germany and back.

And, it was a Polish engineer who made the suggestion to switch the Packard engine with the Rolls Royce engine to increase the P-51 range.

I see that my Comment from almost 2 yrs ago did not result in a “fix” of the Dorsal Fin (:”DFF”_ on the P-51B. Once again, I could give you a correct rendition of the DFF.

Secondly, maybe I didn’t notice it the previous time, but there was NO P-51A at the time that 58 of the 150 NA-91 aircraft were built. The P-51A was the NA-99, the 5th model of Mustang and the NA-91 aircraft was the 3rd, (with the A-36A Mustang in between them). Speaking of the 58 NA-91s (Designated “P-51″ with no letter suffix – although there were camera mods made to most of these for the USAAF and 𝙏𝙃𝙊𝙎𝙀 became the ” P-51-1-NA” – only one of them had this designation), or the P-51-2-NA (most of the USAAF’s NA-91s became these after camera mods were made) “held back” from the Lend-Lease order of 150 for the RAF, the “P-51A” error aside, there were 𝙊𝙉𝙇𝙔 TWO NA-91 aircraft converted to Merlin Mustangs, not three. You state that there was a “third XP-51B” (my words). Where did you get this misinformation from? If I am wrong (I certainly could be, but historians like Bill Marshall, Matt Willis and Bob Gruenhagen (to name only three) would support what I’ve said. If they and I are wrong, then please let me know what the SN was, we’ll research it and get back to you. I say this in ALLLLL honesty: I’d love to be WRONG, if it meant becoming MORE correct – I REALLY mean this!

Once again, I’ll state that this page is VERY good to EXCELLENT, with those few exceptions. There may be other minor ones, but these “stand out.”

Feel free to contact me if you need documentation on what I’ve stated above.

Thank you.

Well, you still haven’t fixed the P-51A error, gang. Here it is 2-3 months later and no edit by y’all.